Harvesting success with great iron and innovative tech

Ever wanted to know where our biggest machines are developed and produced?

That would be Zedelgem, Belgium, home of harvesting since 1906. Today, this global harvesting center of excellence produces our New Holland brand’s industry leading CX, CR and new, award-winning CR11 combine harvesters. It is where customer inspired innovation, great iron and advanced tech come together as one.

We recently announced the latest developments for the site, a €150 million five-year investment plan to expand both research & development and production capabilities.

More than 7,000 new parts are being added to the revamped 50,000 square meter production line. Four new state-of-the-art testing stations will ensure that our machines meet our rigorous standards for product quality as well as the growing demand for higher capacity combines. Additional testing will help us to keep costs down for our farmers while improving productivity out in the field.

Zedelgem’s research and development (R&D) team of over 400 collaborate with R&D colleagues globally at other CNH sites in Europe, North America, South America and India. This means not only is development happening around the clock, it also means we have ‘boots on the ground’ in a variety of different farming environments – close to our customers – to ensure our combines deliver no matter the field conditions. Their work results in 40 to 50 patents each year across all products.

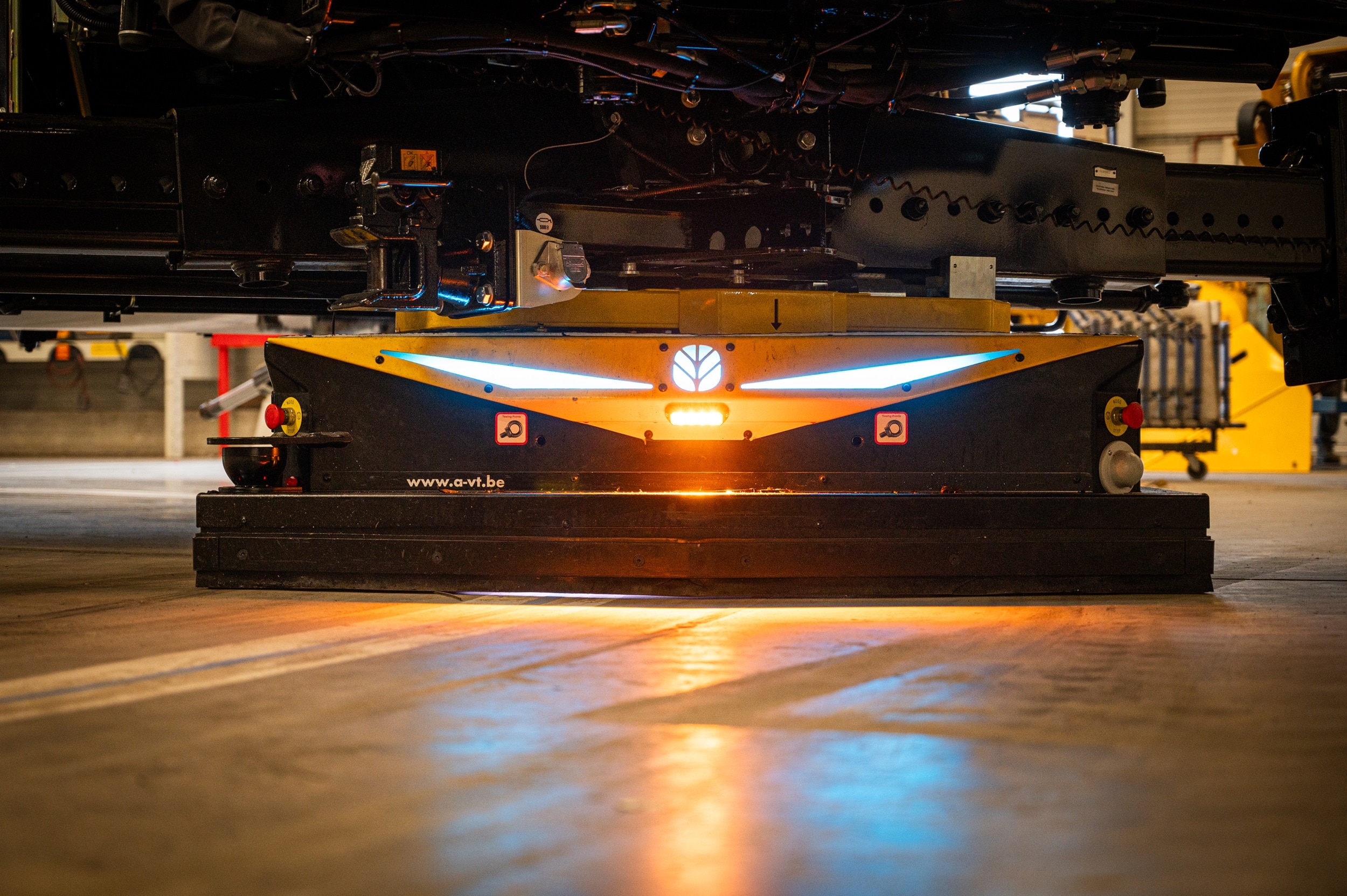

Automation to drive productivity is at the heart of the CR11 combine, and this principle holds true for its production as well. The assembly and logistics area will be completely redesigned using lean principles. Automated guided vehicles will move the combines through the assembly line, creating a safer, more efficient, and more flexible process. The combines will be comprehensively tested and inspected in the four new inline test stations, ensuring the highest build quality.

"For almost 120 years, our Zedelgem Center of Excellence has been renowned for manufacturing cutting edge harvesting equipment, from Europe’s first self-propelled combine harvester to today’s award winning CR11. CNH and our New Holland brand have a leading position in this segment,” said Tom Verbaeten, Chief Supply Chain Officer at CNH.

The New Holland CR11, produced on-site, won the only gold innovation medal at Agritechnica – the agricultural industry’s largest global trade show – in late 2023. This machine delivers the high productivity and yield demanded by our customers, by using advanced artificial intelligence technologies. Its state-of-the-art automation and optimized residue management system will lower operating costs, reduce harvest time, and improve yields. Real-time machine learning, automated predictive adjustments, intelligent fuel management, and unique sensors to understand the crop's nutrient composition are just a few of its extraordinary features.